Knowledge Hub

It’s important to check your final drive on a regular basis and keep up with general maintenance to help improve the lifespan.

- Keeping your final drive clean can make it easier to spot any issues when they first occur rather than them being hidden by grease and dirt, keeping them out of sight.

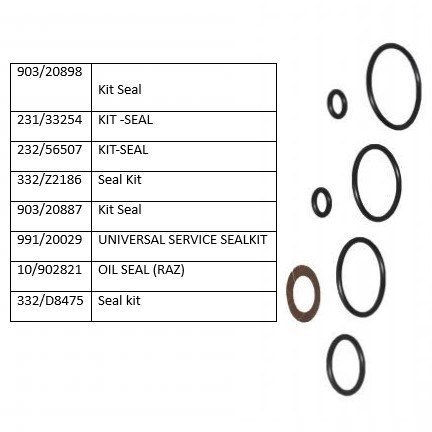

- Check your oil – you can find out how to do this in the operators’ manual. If your oil level is too low this will cause more friction causing damage. If there is a leak you may need to replace the seal.

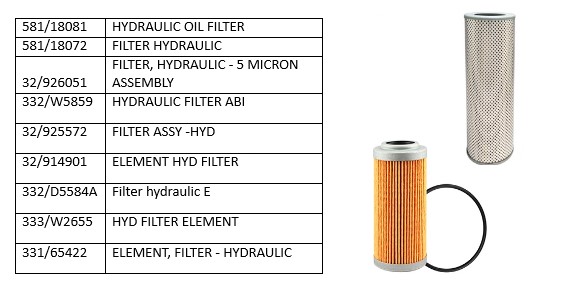

- If your final drive is connected to the machine's hydraulic system, it will be affected by the quality of the machine's hydraulic oil. Therefore, it is important to change your filter on time.

Traction motors available for many makes and models -

Final drives - Plant Spares Online

Final Drives & Parts | UK Construction Parts

Hydraulic / Transmission filters -

Filters | UK Construction Parts

Hydraulic Filters - Plant Spares Online

Seals

Seal Kits | UK Construction Parts

Seals & Seal Kits - Plant Spares Online

#plantsparesonline #ukconstructionparts #sealkits #finaldrive #filter #hydraulicfilter #tractionmotor

There is a specific component that can ultimately render your final drive motor inoperable. The component in question is referred to as the case drain.

The case drain is solely responsible for the link between the final drive motor itself and the hydraulic fluid chamber. Its primary cause is to catch and collect any internal leakages within the excavator's systems and effectively return the not-so-lost fluid away from the operating final drive motor within the excavator.

Any complications with the function of this component alone can be caused to see faulty final drive motor within your excavator.

A good way to ensure this scenario does not happen to your excavator is to conduct frequent inspections of your hydraulic drain filter or case drain system. Either term is referring to the same component so when you hear either phrase being used you’ll know that they are the same.

Not inspecting your case drain filter means that you run the potential risk of clogging in which the leaking fluid instead of being driven away from the final drive motor in turn coagulates on the important functional component itself. We’re sure we don’t have to get too deep as to why this can be a serious problem for your final drive motor; however, to keep things frank, this coagulation will essentially render your final drive motor as “stuck”.

Clogged or malfunctioning case drain filters are, if not the most, one of the most frequent issues an operator will encounter when dealing with a faulty final drive motor.

While keeping a focus on the case drain filter should be toward the top of the list of priorities for frequent inspection, checking your final drive motor’s gear oil takes a close second. This will ultimately help you keep your excavator running for extended periods without much else.

Regular Inspections Are Vital For Your Final Drive Motor Longevity

Whether you're working with heavy equipment or a small machine, maintenance is crucial to keeping everything running efficiently. Don't let yourself become another statistic of blown excavator drive motors.

It is a fact that machines are prone to malfunction at some point in their operational existence. The only way to combat deteriorating machine functions is to adequately conduct inspections of vital components and parts catching any risks for complete mechanical malfunctions as early on as possible.

It is a good habit for any sized excavator operator to conduct an inspection before and after a workload is conducted. At the end of the day, this can save you and your excavator from any mechanical problems or from simply not being able to see an operation through to the end.

Want to know a little more about rubber tracks? If you run a digger smaller than 7.5 ton it’s probably on rubber tracks, but did you know it's not just a black rubber band and what’s inside differs from one manufacturer to another? We have been selling rubber tracks for more than 22 years so I hope I have a very good grounding in most aspects of what you need to know to ensure you get the correct tracks for your machine each and every time!

So for many sizes of #rubbertrack you have 4 options and that is the important stuff!

For example, the basic rubber track size of 400x72.5x74 comes in many common options and it's all to do with the undercarriage fitted to your machine. 400x72.5x74-W is a wide gauge track suitable for early Kubota machines that run a wider sprocket and idler flange, the later Kubota machines often run a 400x72.5x74-R this would be like the picture above they have a reinforced outer ridge for the outer flange bottom rollers to run on, 400x72.5x74-N is a narrow gauge track so has a smaller central gap for the sprockets to run in common on Kobelco and New Holland machines. 400x72.5x74-K is a narrow gauge track with a reinforced roller path for Komatsu machines. And even Yanmar have their own style of track the 400X72.5x74Y these have specially shaped bars in the track to ensure they fit perfectly into the sprocket design they use, so you see it's not just a case of any old track will do!

Can you put the wrong track style on a machine?

Yes you can and many of the cheaper end of the marketplace will use a one size fits all approach, but you generally find they won't last or they keep throwing the tracks off or it’s a rough ride!

Some suppliers will offer cheaper tracks that have a different internal make up, But we offer a no-compromise solution our tracks are longer lasting because we offer a continuous internal wire for strength and a rubber compound designed for the harsh UK working environment, with our many years of experience we know it pays to spend just a little more to get a more cost-effective solution in the long run. (lasting longer so a better cost-per-hour solution)

So when you're ready for your next #rubber #track why not contact the “experts”

We also offer rubber tracks for #trackeddumpers #skidsteers #microdiggers #minidiggers #excavators

Rubber tracks - Plant Spares Online is our webshop but for a more tailored experience please contact the office and ask for Kevin the “trackman”

UK Construction Parts would like to help you get the information you need to keep your machines running, as part of this we are now launching our Knowledge Hub. If there is something you would like to learn about please let us know and we will post it here for all to see.

please find attached guide to how to measure rubber tracks and get the correct ones for your machine.

once you know what you need contact Kevin ( "the track Guy ") for the best prices on quality rubber tracks 01787 320313